Chip Foose: How to Start a Project Car

The process of starting a project car build is both a rewarding and daunting task. The path from finding the right car to seeing the finished product is often long and arduous, marked by late nights, oil-soaked clothes and bruised knuckles. For true enthusiasts, however, this labor of love is worth it. To help make sense of the process, we sat down with the king of custom cars, our friend Chip Foose.

Foose started his career at age seven by helping out at his father’s custom shop, Project Design. By age 12, he had already painted his first car and was well on his way to becoming the builder he is today. Foose graduated with honors from Art Center College of Design in 1990, and after working for private design firms and even OEMs, founded Foose Design in 1998. The firm specializes in illustration, graphics, and ideation, as well as model-making, surfacing, and, of course, the design and construction of cars and automotive products.

Foose has created vehicles for films like “RoboCop,” “Gone in 60 Seconds,” and “Blade Runner.” As host of the popular show “Overhaulin’,” he completed more than 170 cars. Today, Foose-designed customs are sought after by collectors and enthusiasts, noted for their uniqueness and attention to detail.

Getting Started:

According to Foose, the first step in starting a project is “knowing what you want to build before you build it.” This step may seem relatively simple, but for Foose, having an end goal to work toward is vital. He notes that envisioning what you’re going to build helps you save time and money, as it allows you to plan the project’s path. As an illustrator, Foose likes to start his projects with a visual of the build, as that part of the process assists him in defining the finished product.

When it comes to the practical stuff like a budget, he suggests considering what your project means to you. Ask yourself if this project is your dream car, or if it’s a stepping-stone to your dream car. If it’s the latter, make sure you’re not overinvesting and leave room for unexpected costs.

Finding the Right Car

For some, a project car is handed down or stumbled upon, but for others, finding the perfect vehicle is a challenge — sometimes one spanning several years. In these cases, it’s important to keep your eye out for a few specific concerns.

Body condition is foremost to consider, regardless of whether you’re planning on a patinated project or a flawless restored example. Foose says that people often get excited by a ”good deal” when it comes to a project car, but that in the end, it’s often worth paying more for a rust-free car with a straight body. He notes that “sheet metal repairs are expensive, so if you can find a car for the money that’s in better condition, you often end up saving in the long run.”

After taking into account the condition of the project’s sheet metal and frame, you need to consider its completeness. If you’re not planning on doing an engine or drivetrain swap, make sure that the factory running gear is in good shape or, at the very least, restorable. Foose also notes that trimmings such as window moldings, bumpers, and brightwork are expensive components and time-consuming to track down when they are damaged or missing. If you can find a car with most of its trimmings still attached — even if they need some restoration work — you’re generally better off.

Are you going to do a powertrain swap? A new chassis? Custom bodywork? These are all customizations that are often dependent on the type of car you’re going to build. It is best to consider aftermarket support for the vehicle, as custom components take time and money to develop. In some cases, custom parts are what make the project. Planning for that expense, however, is critical.

In the end, Foose says that often it comes down to a gut feeling. He says, “I see a car, and it just feels right, I just have to have it.” In those cases, it’s good to listen to your heart, but don’t forget his list of best practices.

Easiest and Hardest Projects

To wrap things up, we asked Foose about the highlights of some of his projects to date, and he explains that his most straightforward project so far was the buildup of his son’s Mustang. They outfitted the car with a new set of wheels, lowering springs, and Foose Design body components. Although simple by Chip Foose standards, the result is a driver perfect for eating up the miles with style.

Alternatively, many Foose creations are so much more than body components and wheels. He points to Impression, a highly customized ‘30s Ford roadster built for Ken Reister, as the most challenging project to date. The stunning machine began as a sketch on a dinner napkin, but it soon evolved into one of Foose’s proudest accomplishments.

From that original dinner napkin sketch, Foose built a quarter-scale model to take measurements for the custom chassis, and then a full-size wooden buck was made to form the custom sheet metal. The car contains over 4,000 custom parts that were either machined or hand-fabricated. Nearly every piece — from the brackets and trim to the suspension pieces — are unique to this vehicle. There are only three factory parts on the car: the engine, the transmission, and the center section of the rear. Even the tires are custom molded with hand-cut tread.

Impression is part of an elite group of cars to have won both America’s Most Beautiful Roadster Award and the Detroit Autorama Ridler Award, two of the most celebrated achievements in the custom car realm.

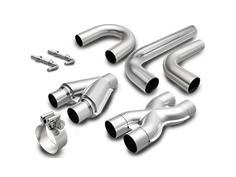

Although not every project will be on the level of Impression, this blog should help get you on the right track to starting a project of your own. We want to thank Chip Foose for taking the time to talk to us, and for sharing some helpful tips from his years of experience. When it comes to your project, remember to make a solid plan, and when it comes to finishing it off with the perfect exhaust, MagnaFlow has you covered.

Need some recommendations or help getting started? Give our Technical Support team a call at 1-800-990-0905.

Comments